BRAND NEW MACHINES BRING UNITED SUCCESS

BRAND NEW MACHINES BRING UNITED SUCCESS

On April 15, 2019, the 16th China International Machine Tool Show (CIMT2019) hosted by China Machine Tool & Tool Builders' Association was grandly opened at the China International Exhibition Center (New Hall) in Beijing, as the most important event held in China this year. The world's machine tool event, CIMT2019 attracted the attention of global manufacturing.

The theme of this year's exhibition is “Integration and Win-win, Wisdom and Future”. This theme accurately and vividly reflects the characteristics of the market and industry development of China's machine tool industry, indicating the future development trend of the industry. As a product of deep integration of manufacturing and information technology, the concept of "smart manufacturing" has been accompanied by the development of information technology and has developed rapidly. With the maturity of digital technologies such as big data, cloud computing, artificial intelligence, and block-chain, the traditional competition logic of the industry is undergoing profound changes. The trend of deep integration of artificial intelligence and advanced manufacturing technology has become the consensus of global manufacturing.

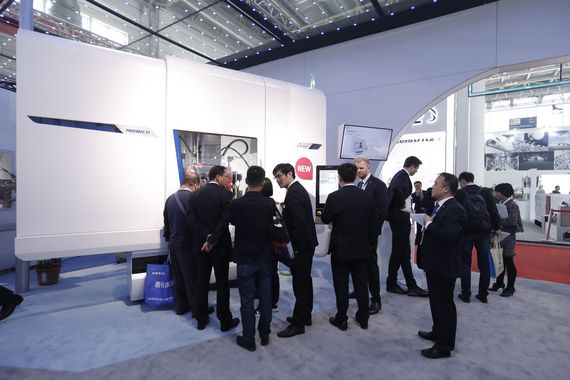

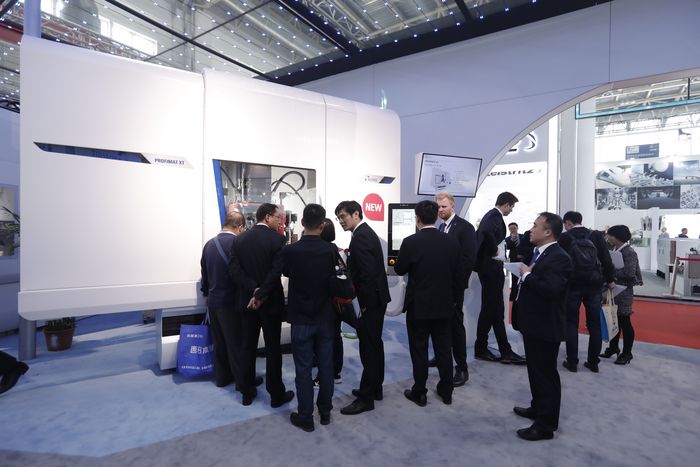

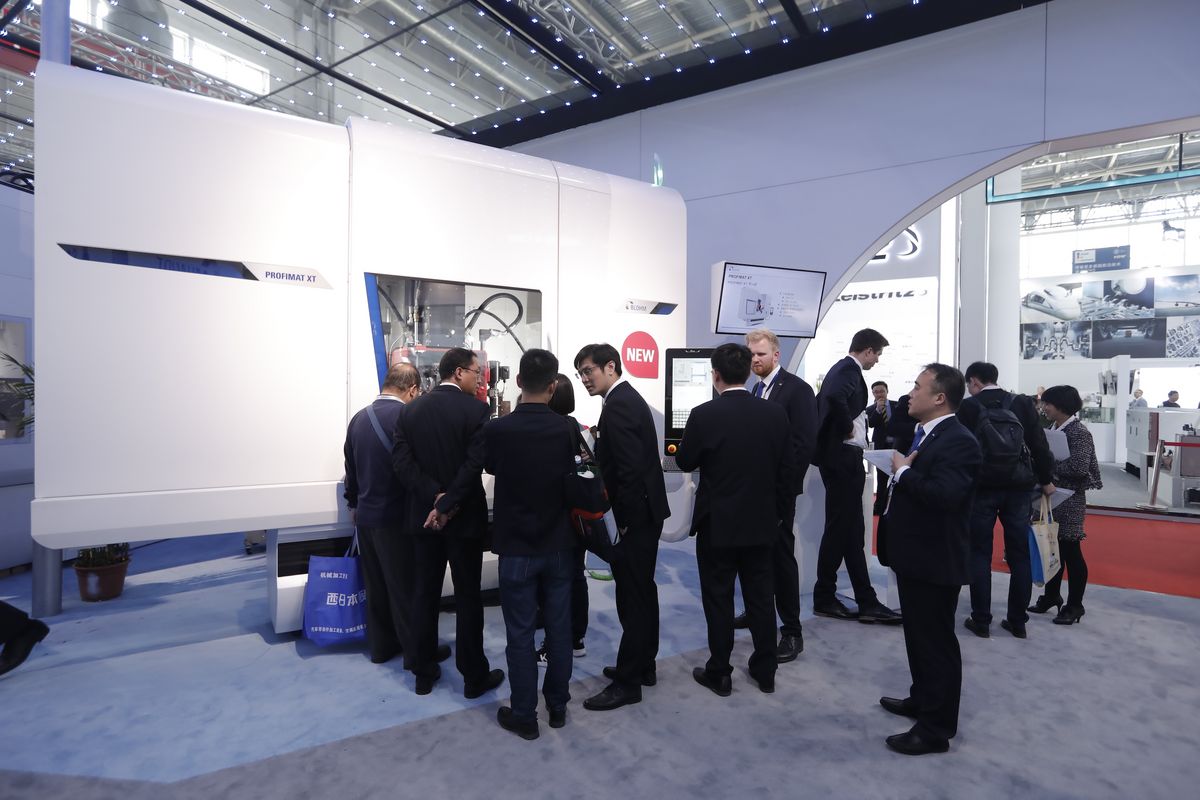

On CIMT 2019. UNITED GRINDING was shown with nearly 500 square meters of booths and 12 machines from home and abroad. Five of these machines were first released at world-class exhibitions. It shows that the UNITED GRINDING Group attaches great importance to the Chinese market.

To meet the diverse needs of everyday production and flexible technology applications, BLOHM has developed a new range of machine tools. The BLOHM PROFIMAT XT is a rugged and high performance production grinding machine based on the experience and quality of the highly successful PROFIMAT MT. Powerful and efficient, this new machine offers excellent prerequisites for the higher demands of everyday production and flexible technical application requirements.

MÄGERLE introduced a new grinding center on the CIMT 2019, the five-axis grinding machine MFP 51, which sets a new benchmark in terms of flexibility and equipment configuration. It is equipped with a gantry-type 66-station integrated tool changer, which enables efficient machining of many different workpieces without the need to modify the tooling. Thanks to the top-loading dresser with a speed of up to 12,000 rpm and integrated in the grinding holder, the machining time with high-speed spindles is very short. The two-axis controlled nozzle greatly optimizes the supply of coolant. In addition, as an option, an identification system for the grinding wheel and the tool is available.

At this exhibition, STUDER brought two new machines based on classic models: S31 and S33. Both new machines feature four new top pitches of 400, 650, 1000 and 1600 mm. Models with distance between centers of 400 mm and 1600 mm expand the existing product line. It can efficiently fulfill the customer's individual needs, and can also use the optional B-axis to complete challenging tasks.

WALTER HELITRONIC G 200 is the first time in the history of WALTER, through the German and Chinese project team to work together to launch new products. Small footprint, good value for money, and equipped with WALTER's world-renowned HELITRONIC TOOL STUDIO tool operating software. Easy to operate and highly flexible.

China's transition from low-tech manufacturing to high-tech manufacturing is accelerating at an alarming rate. Chinese companies' R&D expenditures are among the world's leading. Educational institutions and universities are preparing for the "strongest brain", and they will realize the Chinese dream. UNITED GRINDING Group has not stagnated. We are constantly evolving and we are constantly strengthening and improving our solutions. Our team in China has always maintained an open vision of the changing world around us and tried to understand the requirements and trends of our customers and the industries they serve.

Today, UNITED GRINDING Group has introduced newer and better equipment for high-end precision manufacturing. We established our office in China for the first time 25 years ago. We have been here for 25 years and we fully support our customers to be more excellent, effective and prosperous in the era of technological development in China.