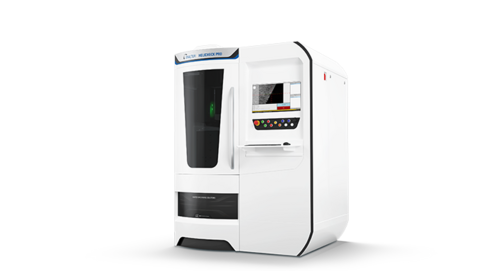

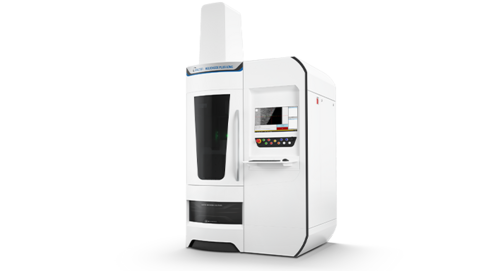

Thanks to the additional 8:1 camera in the HELICHECK PLUS, this CNC measuring machine can also be easily used to capture and measure the smallest geometries on cutting tools. Microgeometries up to 0.1 mm diameter can be measured safely and with high repeatability. HELICHECK PLUS is the right choice to ensure productivity and the quality of modern tool production in a sustainable manner.

Features

Massive granite base

A solid granite base provides the basis for precision and accuracy due to its weight. This granite base provides vibration damping and is thermally stable. These are the prerequisites for very high measurement accuracy and reliable measurement results.

ISO 50 Spindle

The high precision ISO 50 spindle with automatic tensioning mechanism provides precise and repeatable measurements.

Ball screw

High-precision ball screws and linear guides guarantee outstanding positioning accuracy, which is the prerequisite for the most precise measurement results.

Camera systems

The HELICHECK PLUS optical measuring machine is equipped with fixed optical systems without rotating axes. The four camera systems are complemented by LED light sources. Touchless measurement guarantees wear free application and high stability of measurement results.

EUX,MPE Value

The EUX,MPE value of our measuring machine HELICHECK PLUS is (1.2+L/300)µm as standard.

Laser marking and tool cleaning

As an option we offer laser marking as well as cleaning of tools in the robot loader. This increases flexibility in the production and final inspection of your tools. The measuring machine is automatically loaded and the cleaning and laser marking takes place outside the work area.

- Modular adaptor spindle

Quick change adapters can be exchanged quickly and easily without further setup time. The following quick change adapters are available: ISO/HSK/Capto/VDI. - Light table

With this option, which fulfills the function of a coordinate measuring machine, flat parts are developed as part spectrum for measurement. Easy mounting via autocentering and automatic selection of software functions. - Cutting edge rounding

SKV is the logical development for complete measurement including the micro geometries of precision tools. Edge rounding is an important parameter for optimizing tool life and cutting performance. - Digital probe

This option is highly appreciated by operators for measuring extremely small chamfers as well as clearance or rake angles. Also a must for precise measurement of various parameters on threading tools. - Robot loader

Helicheck PRO/PLUS measuring machines can be optionally automated with the proven robot cell from grinding technology. - Cleaning station

Automated cleaning of tools before measuring ensures reliable measuring.