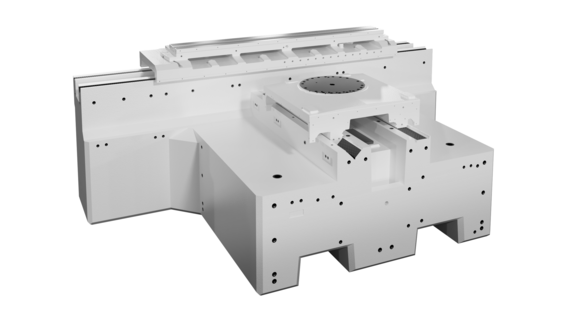

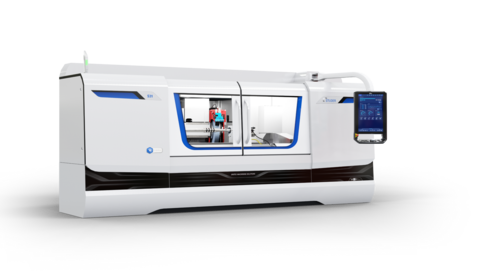

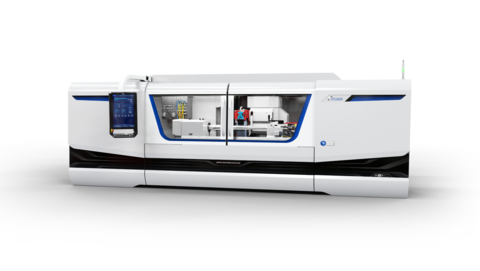

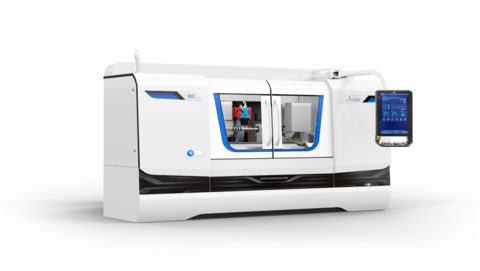

KC33 is suitable for grinding individual and batch production of medium-sized workpieces. It has a distance between centres of 650mm / 1,000mm and a centre height of 175mm. It can machine workpieces with a maximum weight up to 80/120 kg.

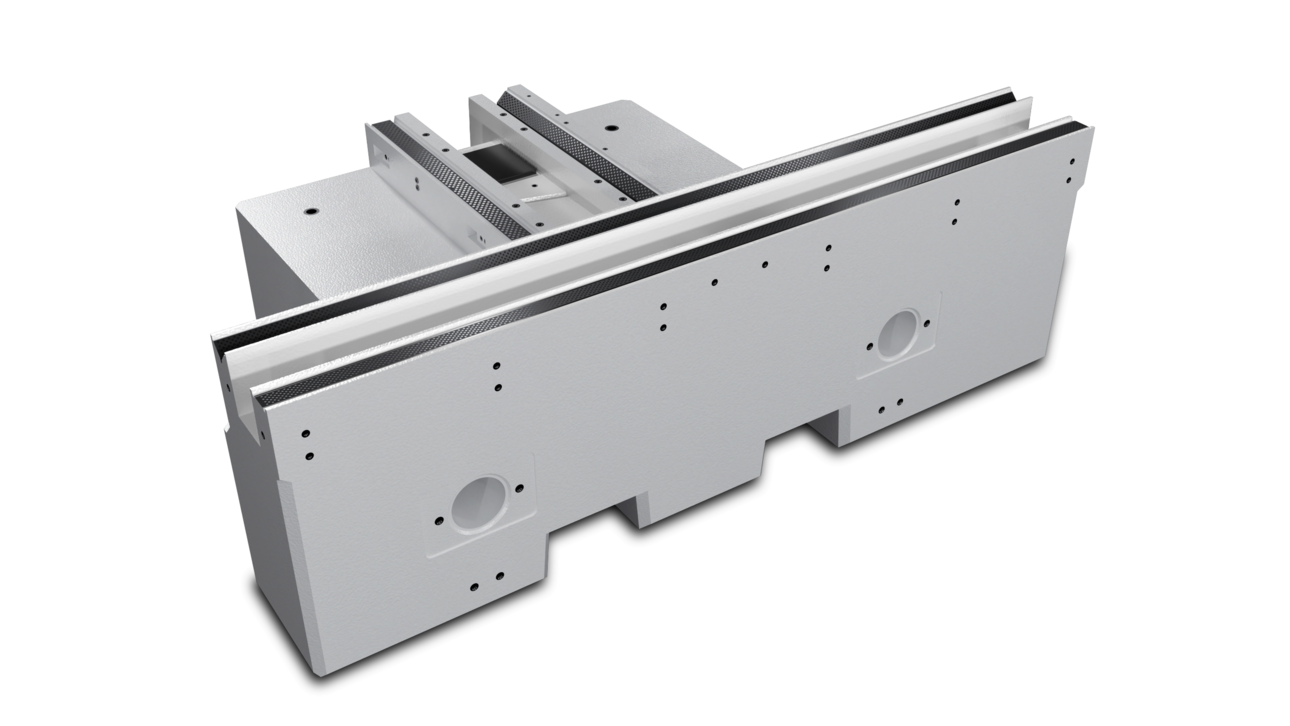

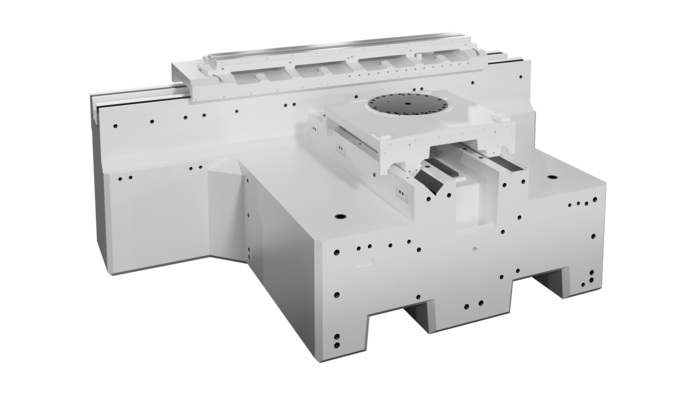

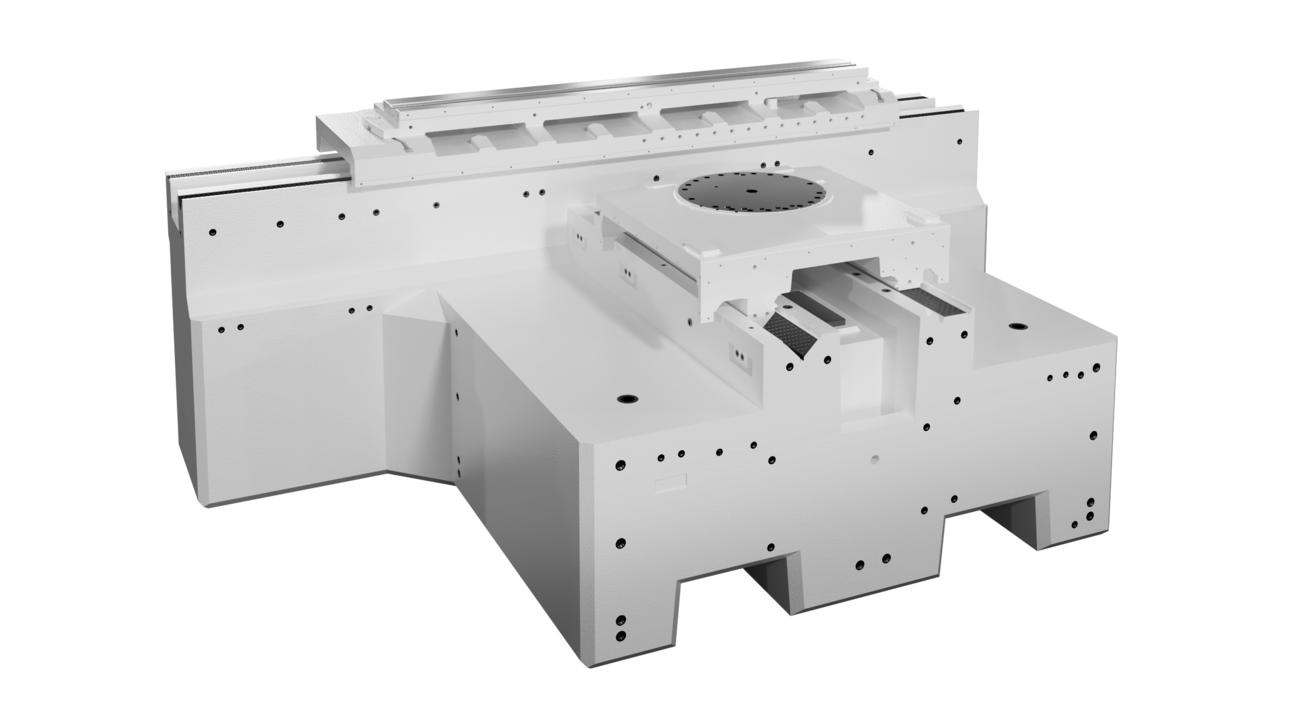

The solid Granitan® machine bed and the top STUDER components ensure the top precision and stable performance. High-precision wheelhead (0.0004mm) and fine-tuning taper (0.0001mm) tailstock ensure machining accuracy. Automatic B-axis, with indexing resolution of 1°, can be equipped with internal spindle and external spindle at the same time, and realize one-time clamping and complete grinding of internal and external complex parts. The fixed grinding wheelhead can be equipped with a cylindrical grinding wheel with a maximum width of 140mm, so as to realize efficient one-time cutting grinding.

Hardware:

- Optional wheelhead:

- Wheelhead Turret can automatically swivel with 1 ˚Graduation, and can manually swivel with 2.5˚Graduation.

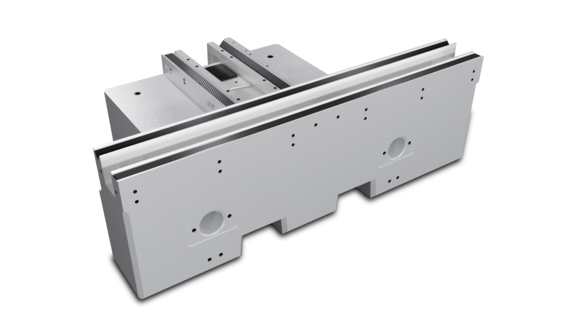

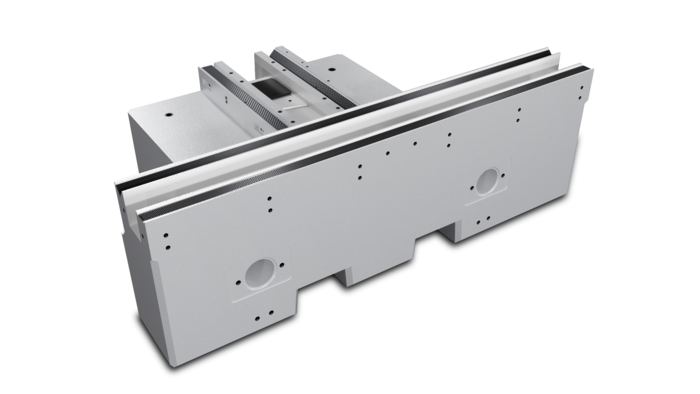

- External wheelhead with grinding wheel on the right, 0° / 15° / 30°, - The Granitan® artificial granite machine bed

Software:

- Using the icon programming interface, programming is easy to learn

- StuderGRIND programming software for creating, grinding and dressing programs on an external PC