The versatile

for big tasks.

Basic Data

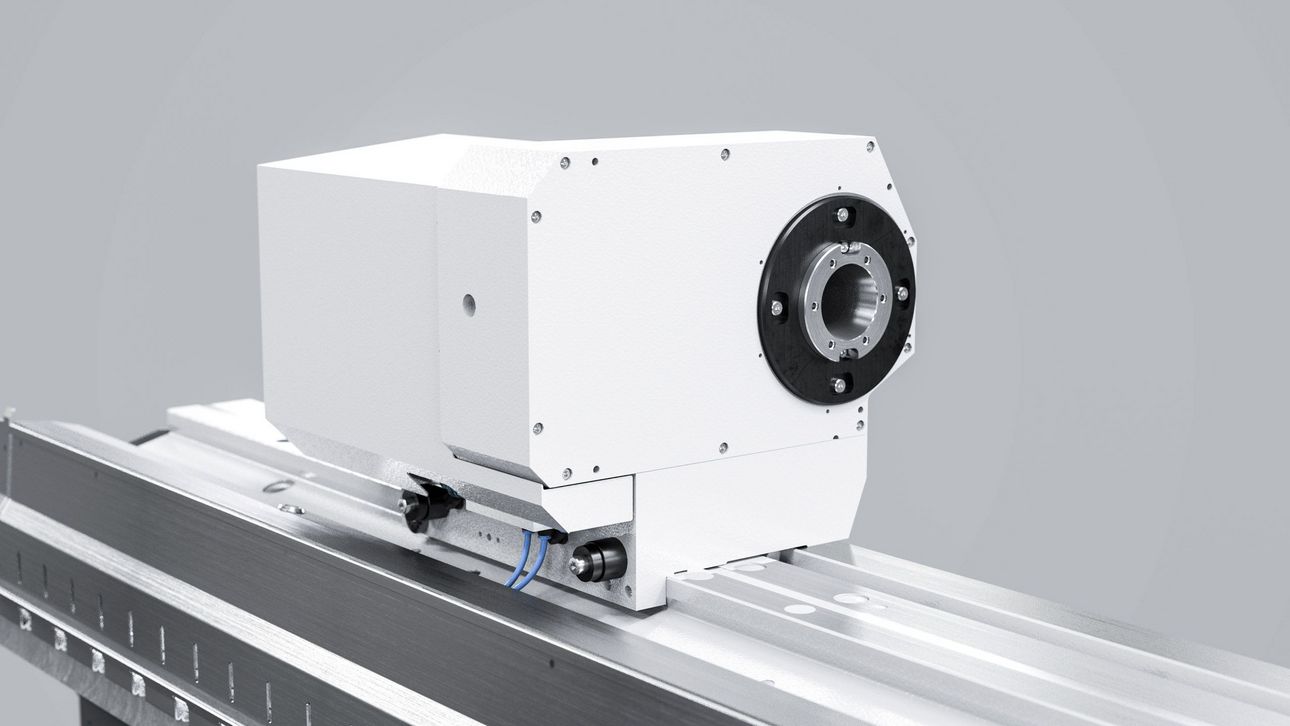

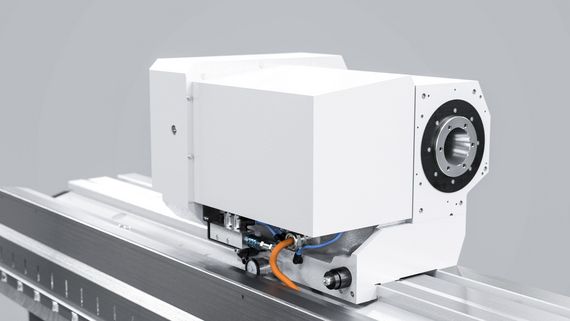

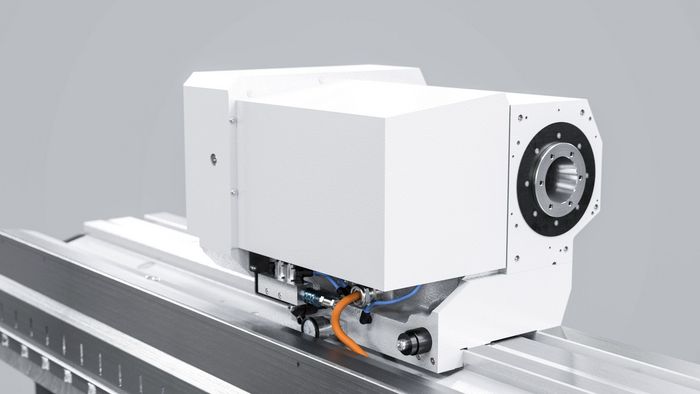

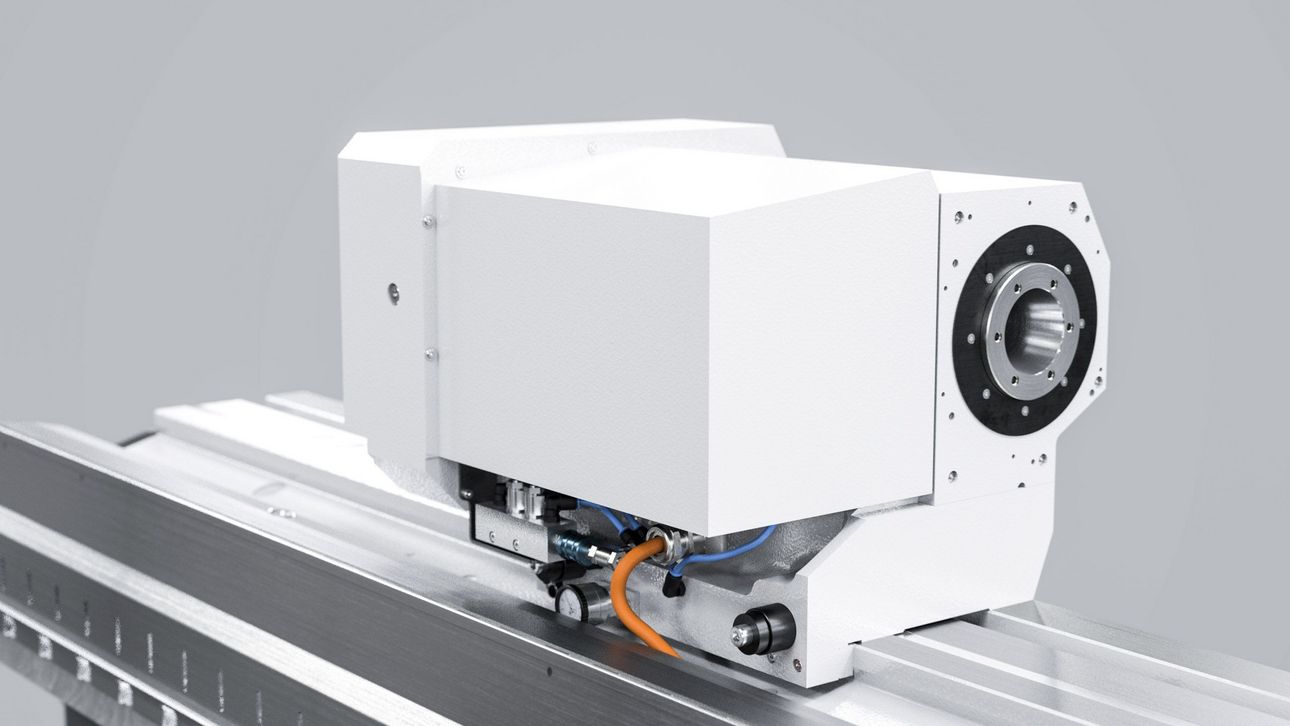

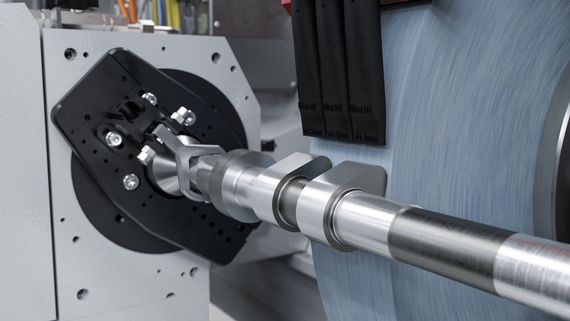

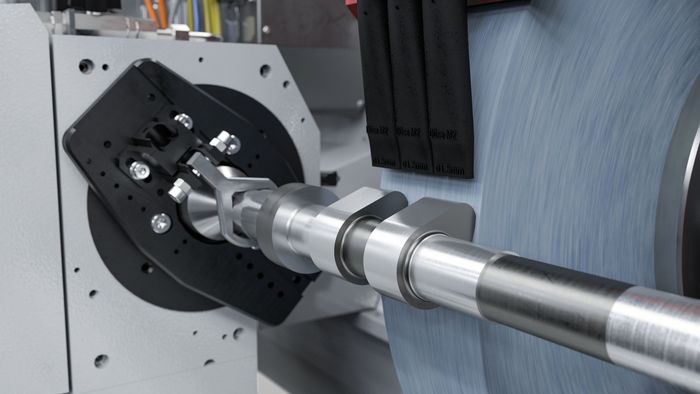

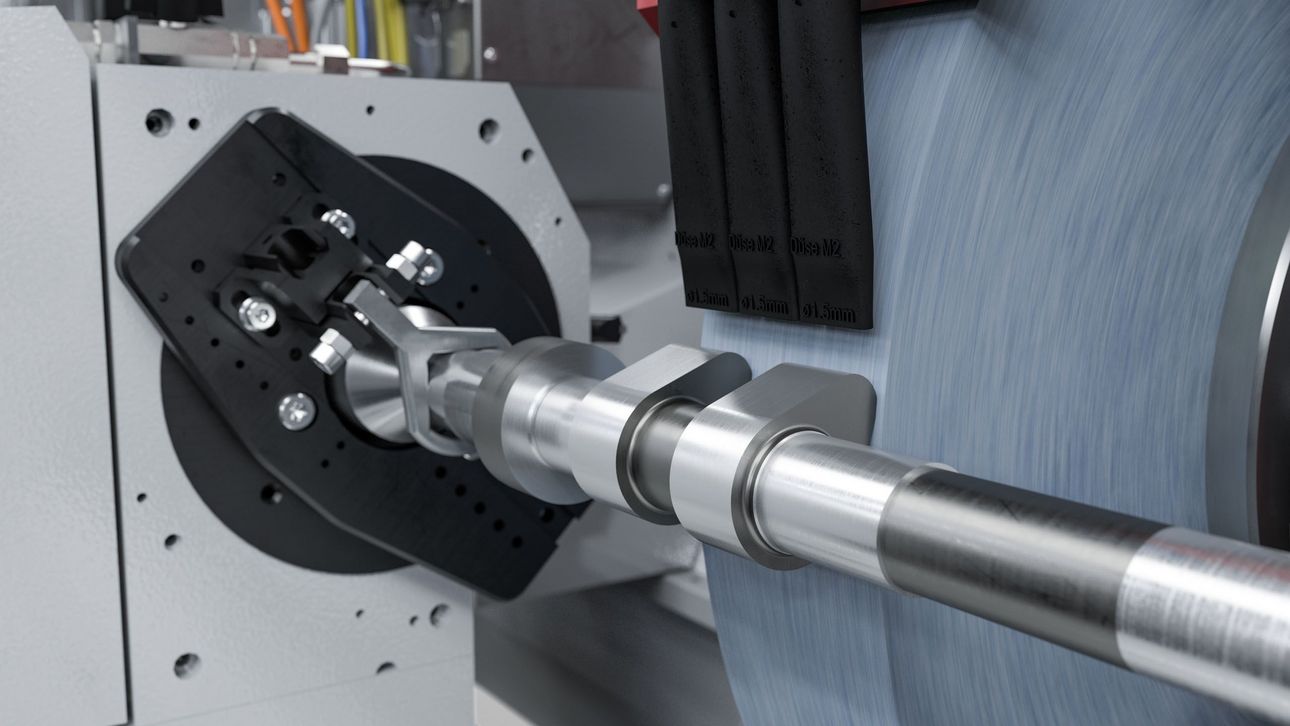

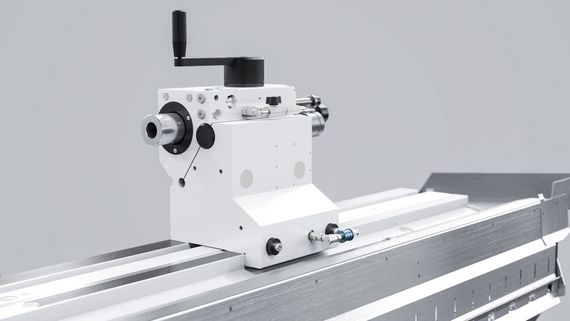

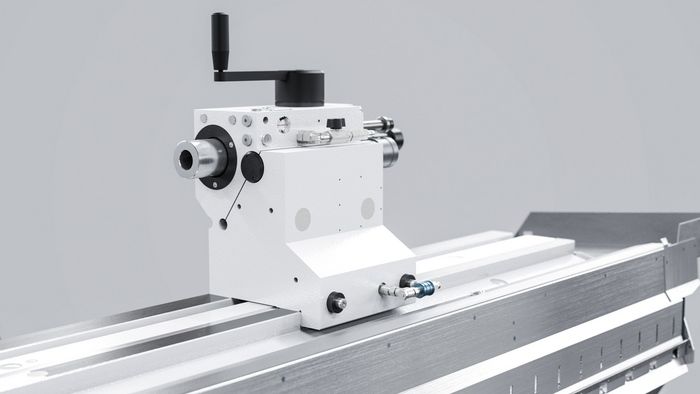

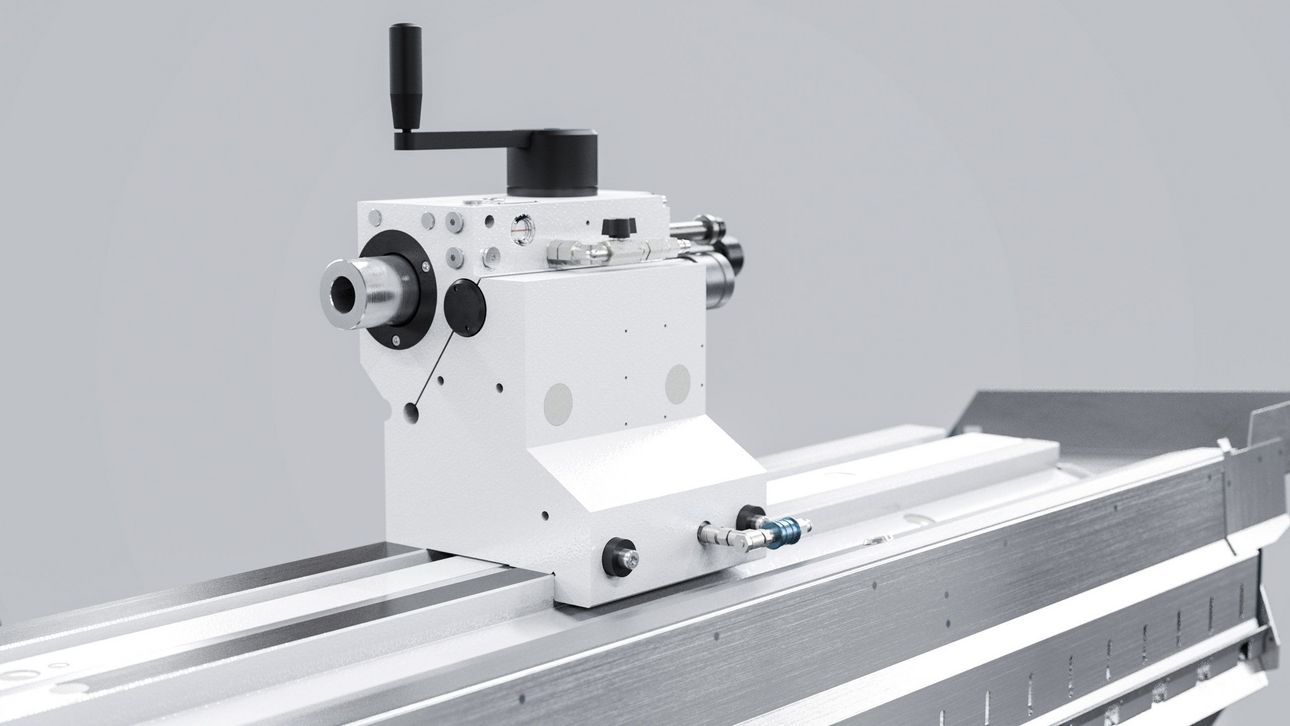

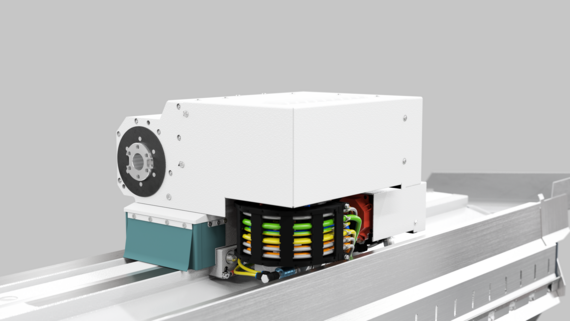

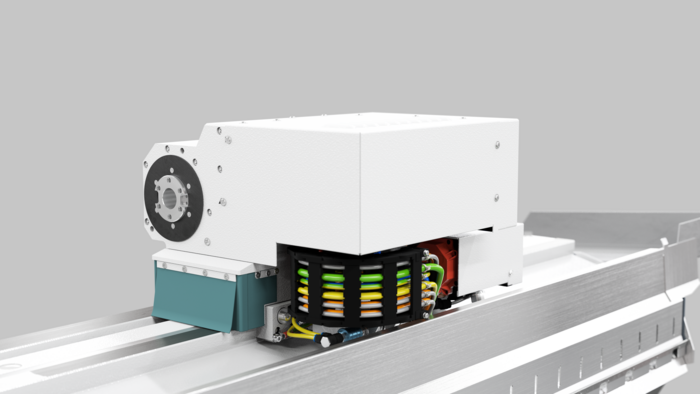

The S31 is a cylindrical grinding machine for small to large workpieces in single, small and large series production. It has a distance between centres of 400mm (15.7") / 650mm (25.6") / 1,000mm (40") / 1,600mm (63") and a centre height of 175mm (6.9"). It can machine workpieces with a maximum weight of 150kg (330lbs).

Thanks to the upgradeable modular system, the S31 can be adapted to match your precise requirements. The swiveling wheelhead allows you to externally, internally and face grind workpieces in a single clamping – with a high-resolution B-axis of 0.00005°. Its foundation is a machine base made of solid Granitan® S103.

Images

Hardware / Software

Hardware:

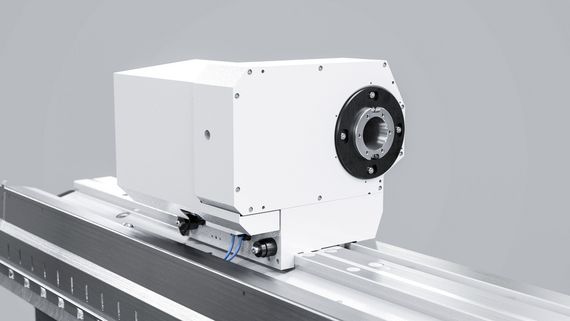

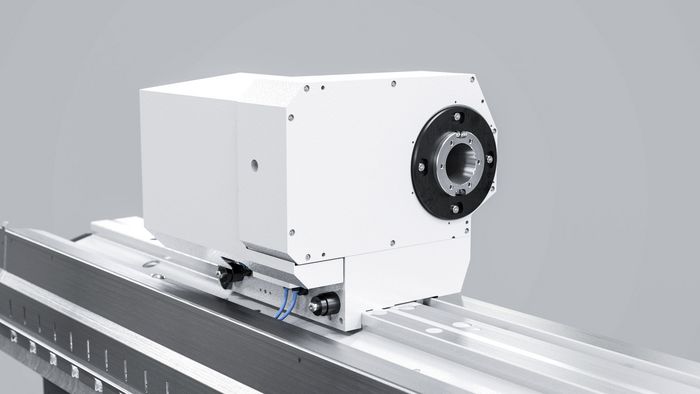

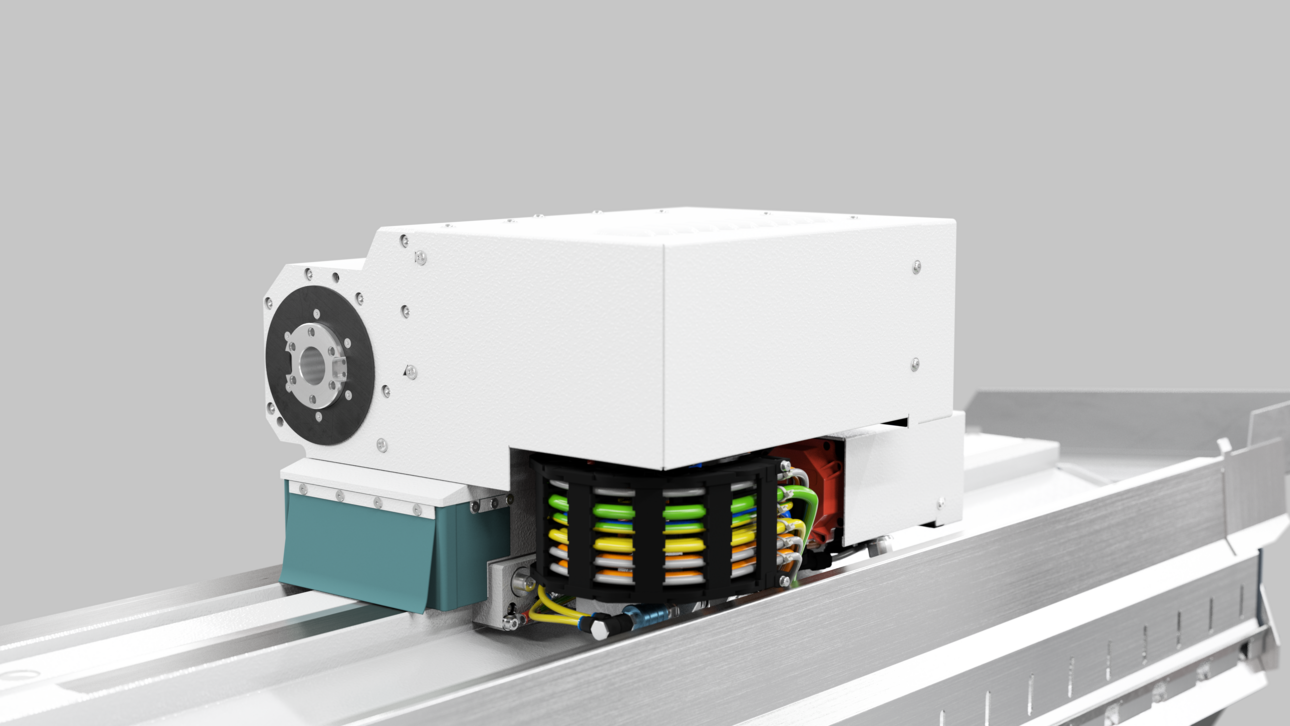

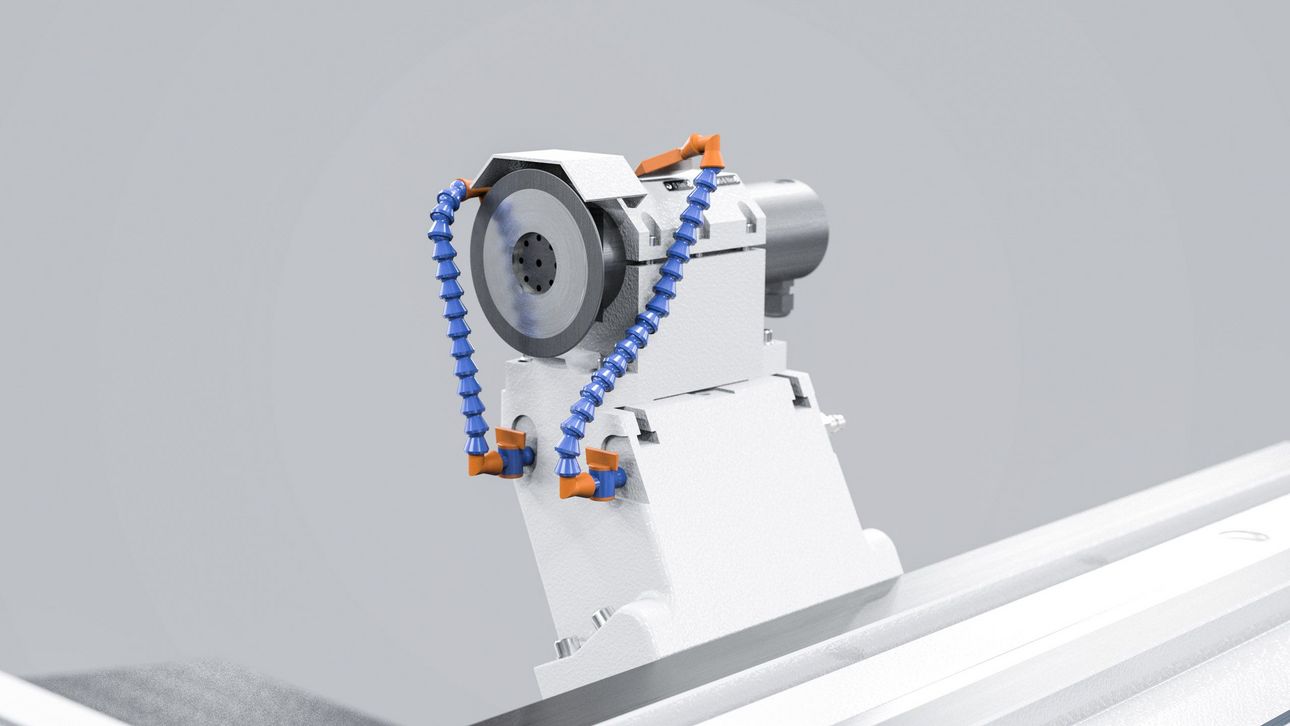

- Turret wheelhead with the option of:

– Stepless B axis

– B axis with 1° Hirth serration - Frequency-controlled motor-driven grinding spindles for external and internal grinding

- C-axis for the workhead for form and thread grinding

- C.O.R.E. Panel

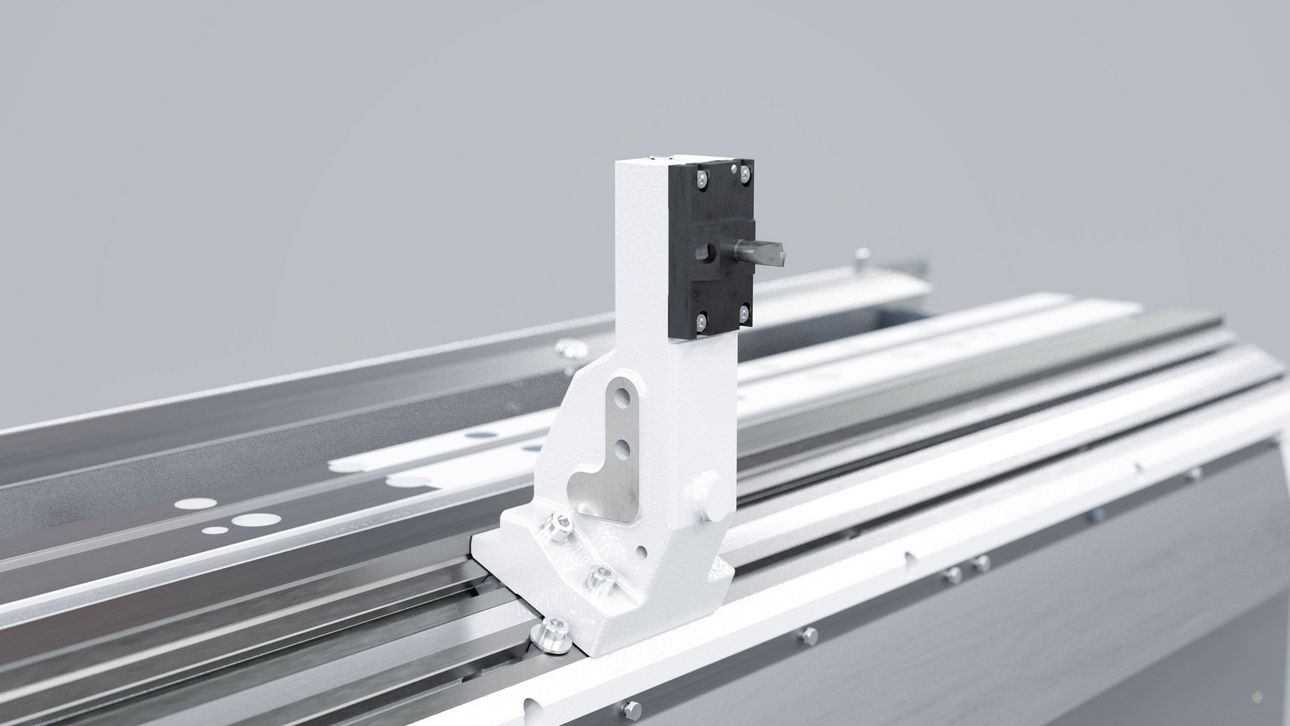

- Tool table with integrated double T-slot for dressing devices

- Full enclosure with two sliding doors

- Granitan® S103 mineral casting machine base

Software:

- C.O.R.E. OS Operating system

- Very simple programming thanks to Studer- Pictogramming

- Reduced setup and resetting times with STUDER QuickSet

- High-speed machining (HSM) for efficient and high-precision form grinding

- Standardized interfaces for loader and peripheral devices

- Flexibly expandable with integrated software modules

- StuderWIN programming software (optional) for creating grinding and dressing programs on an external PC

Technical Data

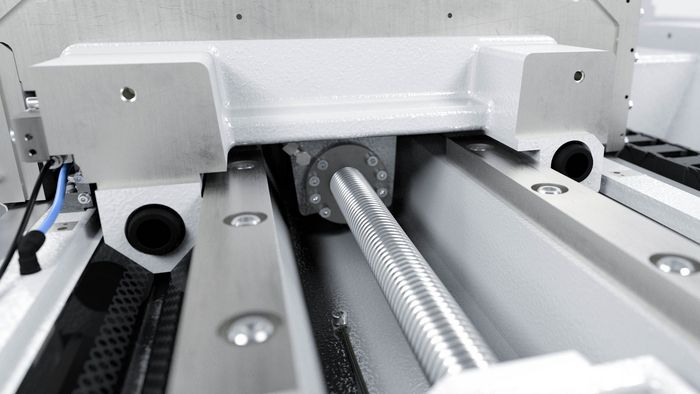

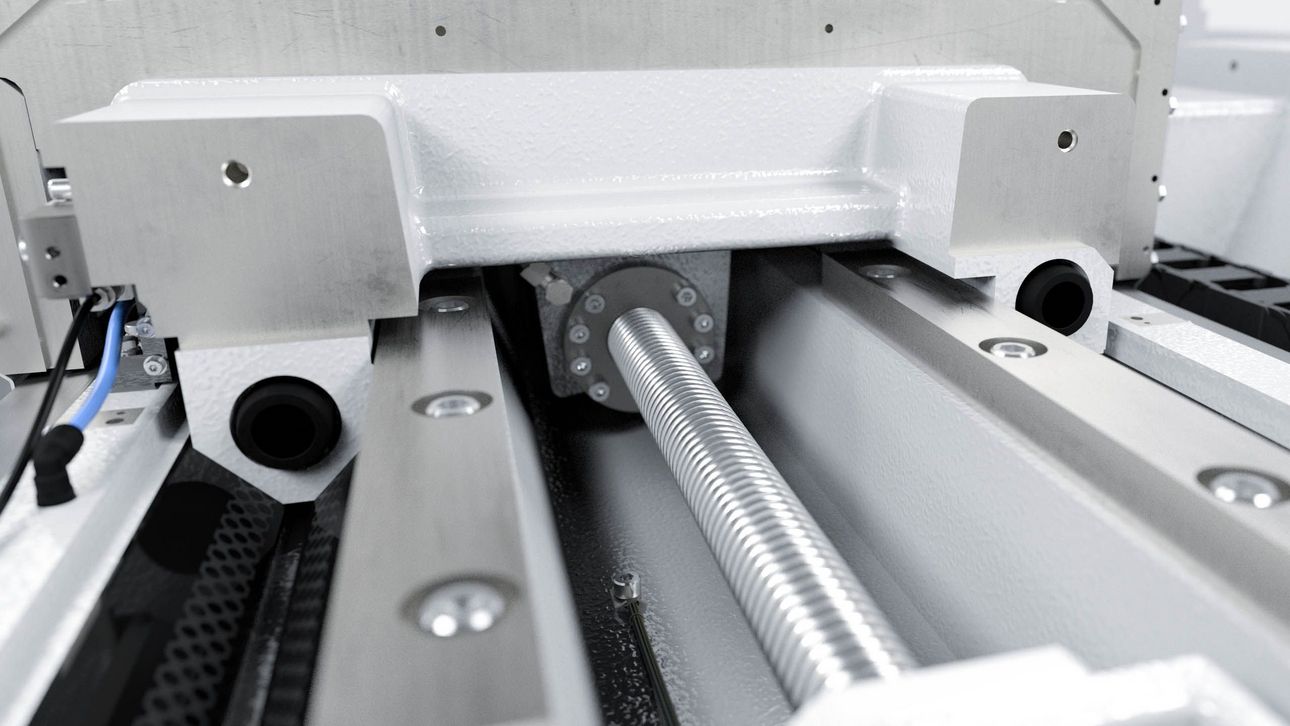

Linear Axes

Max. Travel X

370 mm

Max. Travel Speed X

15'000 mm/min

Max. Travel Z

500 mm

Max. Travel Speed Z

20'000 mm/min

Spindle drive

Max. Spindle Power

11.5 kW

Max. Number Of Revolutions

3'200 /min

Max. Grinding Wheel Diameter

508 mm

Max. Grinding Wheel Width

80 mm

Swiveling Axes

Swiveling Range B

255 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

400 mm

Workpiece Diameter

349 mm

Max. Workpiece Weight

150 kg

Distance Between Centers

400 mm

Center Height

175 mm

Linear Axes

Max. Travel X

370 mm

Max. Travel Speed X

15'000 mm/min

Max. Travel Z

800 mm

Max. Travel Speed Z

20'000 mm/min

Spindle drive

Max. Spindle Power

11.5 kW

Max. Number Of Revolutions

3'200 /min

Max. Grinding Wheel Diameter

508 mm

Max. Grinding Wheel Width

80 mm

Swiveling Axes

Swiveling Range B

255 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

650 mm

Workpiece Diameter

349 mm

Max. Workpiece Weight

150 kg

Distance Between Centers

650 mm

Center Height

175 mm

Linear Axes

Max. Travel X

370 mm

Max. Travel Speed X

15'000 mm/min

Max. Travel Z

1'150 mm

Max. Travel Speed Z

20'000 mm/min

Spindle drive

Max. Spindle Power

11.5 kW

Max. Number Of Revolutions

3'200 /min

Max. Grinding Wheel Diameter

508 mm

Max. Grinding Wheel Width

80 mm

Swiveling Axes

Swiveling Range B

255 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

1'000 mm

Workpiece Diameter

349 mm

Max. Workpiece Weight

150 kg

Distance Between Centers

1'000 mm

Center Height

175 mm

Linear Axes

Max. Travel X

370 mm

Max. Travel Speed X

15'000 mm/min

Max. Travel Z

1'750 mm

Max. Travel Speed Z

20'000 mm/min

Spindle drive

Max. Spindle Power

11.5 kW

Max. Number Of Revolutions

3'200 /min

Max. Grinding Wheel Diameter

508 mm

Max. Grinding Wheel Width

80 mm

Swiveling Axes

Swiveling Range B

255 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

1'600 mm

Workpiece Diameter

349 mm

Max. Workpiece Weight

150 kg

Distance Between Centers

1'600 mm

Center Height

175 mm